Skye Metal Coating is the Best Electroplating & Metal Coating Company in Dubai, UAE

Gold Plating

We offer Gold plating services in Dubai. We strictly follow ASTM standards for Hard Gold plating. Our quality is second to none.

Silver Plating

We provide Silver plating services in Dubai. All our silver plating process is in accordance with ASTM standards.

Anodizing Aluminium

We are one of the top Anodizing companies in Dubai, UAE. We offer anodizing services on Aluminum and titanium.

Tin Plating

Skye provides more efficient tin plating in Dubai. Our clients require tin plating on copper bus-bars. We also provide certificate of conformance.

Nickel Plating

We offer nickel plating and electroless nickel plating service in Dubai. We provide your required thickness with certifications.

Copper Plating

We offer the best copper plating in UAE. Our tank sizes are huge. Hence, we can accommodate bigger materials upto 4 meters in length.

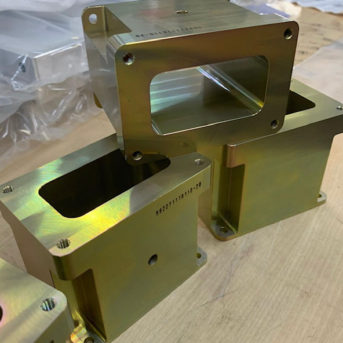

Chromate Conversion Coating

Chromate conversion coating on aluminium parts is one of the coating services we provide by passivation process. We work extensively for military parts.

Passivation

We offer pickling & passivationin dubai for your steel parts. Passivation process is carried out in order to prevent corrosion. Our parts can also be salt spray tested.

Black Oxide Coating

Our services include Black oxide coating in dubai on Mild Steel parts. Our finished products are of super high quality. We follow the required ASTM standards.

Chrome Plating

We offer Chrome Plating in Dubai. Our decorative chrome plating quality is one of the top in the metal coating industries. Our tanks are 4m long so you can expect faster delivery.

Galvanizing in UAE

Skye metal coating offers electrogalvanizing in Dubai including yellow, blue, black, silver, green passivation. Our Zinc plating in dubai process always passes the salt spray test.

Powder Coating Dubai

We offer ISO certified powder coating in Dubai, UAE. Currently, we are the leading powder coating company in UAE. We offer COC for our work and literally located near you.

Cadmium Plating in Dubai

We offer Cadmium Plating service in Dubai, UAE. Our plating quality is the top in aerospace industry. We follow military standard for top electroplating service near you.

Electroless Nickel Plating in Dubai

Skye metal coating in UAE offers electroless nickel plating in Dubai with higher required thickness. We follow required ASTM standards for metal coating in dubai.

Brass Plating in Dubai, UAE

We offer ISO 9001 certified brass plating in Dubai, UAE. We can do electroplating on stainless steel, aluminium, mild steel or any alloys.

Best Metal Coating & Electroplating Company in Dubai, UAE

Skye metal coating provides both Powder coating and Electroplating services such as Gold plating, silver plating, Anodizing, Tin plating, Nickel plating, Chrome plating, Galvanizing, Zinc Plating, Black oxide, Chromate conversion coating, Electroless nickel plating, etc., Being the leader among metal coating companies in UAE, we offer excellent customer support and on-time delivery for all your parts. Feel free to choose the top metal coating company in Dubai.

About Us

Skye Metal Coating helps local metal fabrication companies by providing Electroplating, Powder coating and metal coating services in Dubai, UAE through long lasting and mutually rewarding relationships.

At Skye, we work with our partners to streamline project plans that don’t just deliver on product perfection, but also delivers on time. As of 2024, among all the electroplating companies in dubai, we are the best metal coating company in Dubai, UAE.

Our metal coating dubai team offers the most up-to-date metal fabrication and coating company services in Dubai, UAE . We only source materials from trusted suppliers that meet our exacting standards of quality control. For 4 years in a row, we have been providing all common types of metal coatings and are currently one of the leading powder coating companies in Dubai, Abu Dhabi, Sharjah, Ajman, Umm Al Quwain, Ras al Khaimah and Al ain.

What has been said (Reviews)

Their work is of such outstanding quality, they are clearly experts in their field.

– M. Khalifa

For any plating task, Skye metal coating are by far the most innovative in the industry.

– Ibrahim

The creativity we encountered in skye was simply world class.

– Muhammad

There is incredible peace of mind knowing that you’re in the hands of professionals.

– Khalil

“We help big companies integrate our metal plating technology and scale it without any compromise in quality”

Our Team

Dr. Joseph Sharkey

Managing Director

Er. Keerthi Priya

Head of Operations

Er. Sivaraja. K

Plant Manager

Mr. Hussain

Head of Innovation

We’re always interested in new projects, big or small. Please don’t hesitate to get in touch with us regarding your project.

If you want to contact us about any issue please call 044230853 or +971507045388 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.