Skye Metal Coating LLC offers chromate conversion coating on various aluminum parts. We work closely with military and aerospace companies. Skye offers protective coating and a thin film that will improve the conductivity of the surface. In addition, we are quite flexible with using the requested chemicals for the chromate conversion coating so please feel free to send us an enquiry. We are located in Dubai. However, our services are done all over the emirates.

Alodine or Iridite or Chem Film Coating

Chromate Conversion Coating On Aluminium

Chromate conversion coating, also known as chemical conversion coating or chem film, is a metal finishing process that protects aluminum and its alloys against corrosion. They are created through a passivation process.

The chromate conversion coating process begins by thoroughly cleaning the aluminum part to remove any contaminants. The part is then dipped into a solution containing hexavalent chromium, which reacts with the surface of the aluminum, forming a protective layer.

This method renders the coated surface structure chemically inactive. A complex metal-chrome molecule film forms around the metal, which eventually forms into a continuous gelatinous coating. This type of gelatinous coating effectively eliminates the chemical reaction process, which is what causes corrosion. After the chem film is applied, the part is rinsed and dried to complete the process.

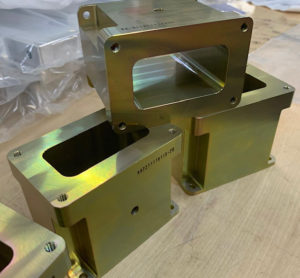

Companies use chem films or chemical films for corrosion resistance and as a paint base. When there is a need for both electrical conductivity and corrosion resistance, chem film becomes a good choice. The coating is available in iridescent yellow and clear colors, but it is important to note that the yellow color offers superior corrosion resistance. The lighter color provides lower electrical resistance. Additionally, it is worth noting that chemical film is fragile immediately after processing, and it is preferable to wait for 24 hours before handling the parts.

Advantages of Chromate Conversion Coating in Dubai

Chromate Conversion Coating On Aluminum 6061 and 6063

Chromate conversion coatings provide excellent corrosion protection to the metal on which they are applied, similar to the way passivation works on steel parts. Industries such as military and defense find them particularly valuable since they subject aluminum components to harsh environments. The chem film forms a chemical barrier that prevents moisture and other corrosive elements from reaching the underlying metal surface.

One of the advantages of chromate conversion coating aluminum is their ability to passivate aluminum. The chem film enhances the natural oxide layer on the aluminum surface, further increasing its corrosion resistance. This makes it an ideal pre-treatment for subsequent processes such as painting or bonding.

They also serve as a base for other finishes, such as anodized surfaces. The chem film provides a suitable surface for adhesion, improving the durability and appearance of the final coating.

It is worth noting that hexavalent chromium has raised environmental and health concerns. As a result, regulations in some countries, including the United States and United Arab Emirates, have limited its use. However, alternative coatings and processes that comply with environmental regulations, such as trivalent chromium-based chem films or trivalent chromate conversion coating, have been developed to provide similar levels of protection.

The specific requirements for can vary depending on the industry and application. Chromate conversion coating standards such as MIL-DTL-5541 Type II and Type III outline the requirements for coatings on aluminum parts, specifying parameters such as coating thickness, electrical conductivity, and resistance to corrosion.

In summary, chem film is a chemical process used to protect aluminum and its alloys against corrosion. The process involves applying a thin layer of chem film using hexavalent chromium. This passivates aluminum, enhances corrosion resistance, and serves as a base for other finishes. However, environmental regulations have limited the use of hexavalent chromium. As a result, various industries and applications have developed alternative coatings to meet their requirements.

Standard Specification No:

MIL-C-5541F Chemical Conversion Coatings on Aluminum and Aluminum Alloys

CONTACT US HERE!