Nickel Plating in Dubai, UAE

Nickel electroplating is the backbone of decorative electroplating. Nickel has properties which allow it to shine, throw into corners and even smooth out surfaces. It is the undercoating for most shiny plating surfaces. Nickel itself has a very nice color. The chrome can sometimes look cold with its blue tint; but nickel has a warmer, yellow-brownish tone. It is a common finish on coal stoves, and antique items.

nickel plating

Nickel plating is extensively used in a range of decorative applications just like gold plating. These include components for the automotive, cycle and marine industries, household appliances, door furniture, hardware items, jewellery and a wide variety of consumer items.

The principle purpose of decorative plating is to enhance the appearance and decorative appeal of the articles, however the coatings may also be required to meet stringent performance criteria. The criteria may include adhesion, ductility, corrosion resistance, etc. depending on the application and service conditions.

When a bright or lustrous finish is required, it’s advisable to opt for bright watts nickel plating. These systems contain organic additives that refine nickel’s grain structure, yielding a self-leveling effect for enhanced luster. However, these additives may compromise solderability and brazing while resulting in a more tensile-stressed deposit with reduced ductility.

Nickel Plating Steel Parts

For applications involving soldering, brazing, or laser welding, sulfamate nickel electroplating is recommended. Sulfamate nickel produces a highly pure nickel deposit, free of organic additives, resulting in a 99.9% pure nickel deposit with a satin to dull appearance. Unlike traditional brightened watts nickel systems, sulfamate nickel creates a compressively stressed deposit, making it an excellent choice for crimping or flexing applications and as an underplate for gold plating applications, including lead frames and interconnect pins.

As a general guideline, un-brightened nickel deposits like sulfamate nickel provide optimal corrosion resistance, as co-deposited inorganic compounds can degrade corrosion performance.

Nickel Plating Process

A. Surface Preparation

Before nickel coating, meticulous surface preparation is crucial. Skye Metal Coating employs advanced techniques to ensure that the substrate is properly cleaned and prepared for the electroplating process.

B. Electroplating Process

The electroplating process involves immersing the prepared surface in a nickel electrolyte solution and passing an electric current through it. This results in the deposition of a uniform layer of nickel, adhering seamlessly to the substrate.

C. Quality Control Measures

Skye Metal Coating maintains strict quality control measures throughout the nickel plating process. This ensures that the finished products meet the highest standards of quality and durability.

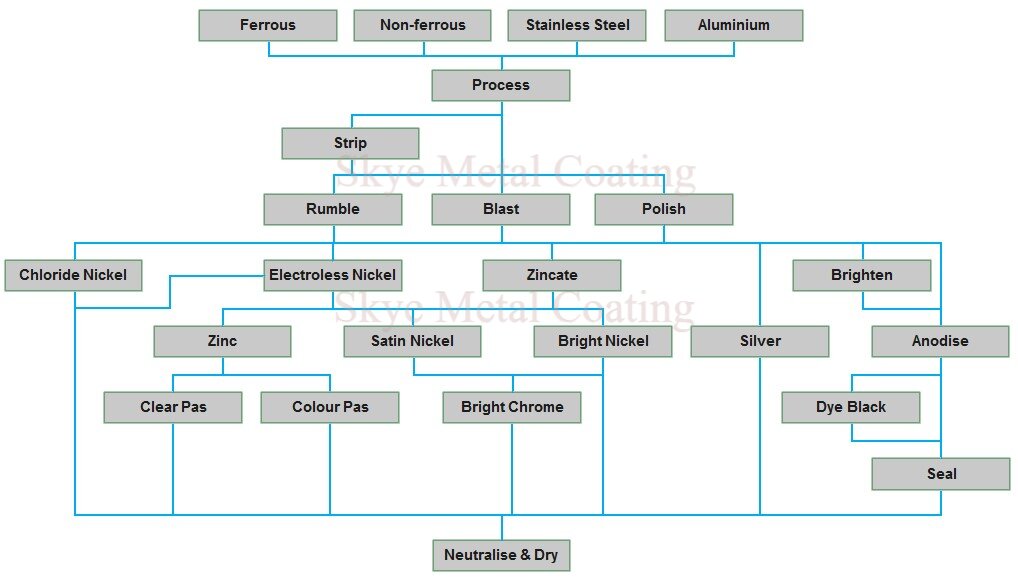

Nickel Plating Dubai – Process Flow Chart

Advantages of Nickel Plating In UAE

A. Corrosion Resistance

Nickel-plated surfaces exhibit exceptional resistance to corrosion, making them ideal for products exposed to harsh environmental conditions. This advantage significantly extends the lifespan of the plated items.

B. Enhanced Durability

The additional layer of nickel contributes to the durability of the coated items, protecting them from wear and tear. This is particularly beneficial for components in machinery and equipment.

C. Decorative Appeal

Beyond its functional benefits, nickel coating in UAE adds a touch of elegance to products. The smooth and lustrous finish enhances the visual appeal, making it suitable for decorative applications.

Applications of Nickel Plating

A. Automotive Industry

Nickel-plated components play a vital role in the automotive industry, providing enhanced durability and corrosion resistance. From engine parts to decorative trims, just like chrome electroplating, nickel electroplating finds diverse applications.

B. Electronics and Electrical Components

In the electronics sector, nickel plating is essential for protecting components from environmental factors and ensuring reliable performance. It is commonly used in connectors, switches, and other electronic parts.

C. Aerospace Applications

The aerospace industry relies on nickel-plated parts for their exceptional strength and resistance to harsh conditions. Skye Metal Coating’s expertise extends to catering to the specific requirements of aerospace applications.

Standard Specification No:

ASTM: B 689 – 18 – Electroplated Engineering Nickel Coating

ELECTROLESS NICKEL PLATING

Electroless Nickel Plating Service

Electroless nickel is a plating process which deposits an even layer of a nickel-phosphorous alloy on a part. Its properties include corrosion resistance, hardness, and abrasion resistance. A typical thickness of plating varies from 0.000050″ to 0.002″ thick. The beauty of this process as compared to electrolytic processes is that the coating builds up evenly on all surfaces the solution touches with adequate circulation. Our process deposits approximately 87-89% nickel & 11-13% phosphorous coating which is considered a “High-range” alloy. Other processes with less phosphorous produce coatings with less corrosion resistance and more hardness. Processes with more phosphorous produce coatings with more corrosion resistance and less hardness.

Our Electroless nickel deposit as plated has a hardness of about RC 49 -50 and it can be baked to produce a hardness between RC 65 and 70. Electroless nickel is used on molds, machine parts, valves, aircraft… We perform high quality and safe Nickel plating. We can plate it on aluminum alloys, nickel alloys, steel alloys and copper alloys.

Standard Specification No:

ASTM B733 – 15 Autocatalytic (Electroless) Nickel-Phosphorus Coatings on Metal

Frequently Asked Questions

Q1: Is nickel plating better than Stainless Steel?

A1: The suitability of nickel plating or stainless steel depends on the specific application. Nickel plating offers advantages like corrosion resistance and an attractive finish, while stainless steel provides excellent corrosion resistance and durability. The choice between the two will depend on factors such as corrosion resistance, wear resistance, aesthetics, and cost.

Q2: What industries can benefit from nickel plating services?

A2: Nickel plating is widely used in industries such as automotive, aerospace, electronics, telecommunications, medical, and more. It offers a range of advantages, including corrosion resistance, wear resistance, and enhanced electrical conductivity, making it suitable for diverse applications.

Q3: How long does the nickel plating process take?

A3: The duration of the nickel plating process depends on various factors, including the size and complexity of the object being plated. Generally, small to medium-sized projects can be completed within a few hours to a few days. Larger or more intricate projects may require more time.

Q4: Is nickel plating environmentally friendly?

A4: Nickel plating, when performed using environmentally conscious practices, can be a relatively eco-friendly process. Skye Metal Coating follows strict environmental regulations and employs sustainable techniques to minimize waste and reduce the impact on the environment.

Q5: Can nickel plating be applied to non-metallic surfaces?

A5: Nickel plating is primarily used for metal surfaces. However, certain non-metallic materials, such as plastics and ceramics, can be pre-treated with specialized processes to enable nickel plating.

Q6: How should nickel-plated objects be maintained?

A6: Nickel-plated objects require regular cleaning to maintain their appearance and longevity. Mild soap and water can be used for routine cleaning, while specialized nickel cleaners are available for more stubborn stains. Avoid abrasive cleaners or scrubbing tools that can damage the plated surface.

Q7: Can nickel plating be done on irregularly shaped objects?

A7: Yes, nickel plating can be applied to objects of various shapes and sizes, including those with complex geometries. Skye Metal Coating’s skilled technicians employ techniques such as brush plating or selective plating to ensure uniform coverage on irregular surfaces.